Thermal Spray Coatings

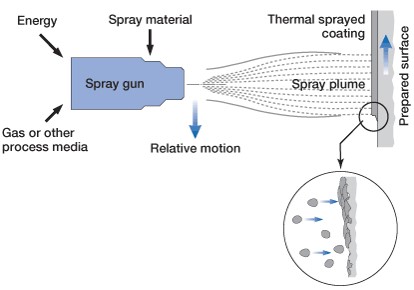

Figure illustrates a typical coating cross section of the laminar structure of oxides and inclusions. The coating that is formed is not homogeneous and typically contains a certain degree of porosity, and, in the case of sprayed metals, the coating will contain oxides of the metal. Feedstock material may be any substance that can be melted, including metals, metallic compounds, cements, oxides, glasses, and polymers. Feedstock materials can be sprayed as powders, wires, or rods. The bond between the substrate and the coating may be mechanical, chemical, or metallurgical or a combination of these. The properties of the applied coating are dependent on the feedstock material, the thermal spray process and application parameters, and post treatment of the applied coating.

Figure illustrates a typical coating cross section of the laminar structure of oxides and inclusions. The coating that is formed is not homogeneous and typically contains a certain degree of porosity, and, in the case of sprayed metals, the coating will contain oxides of the metal. Feedstock material may be any substance that can be melted, including metals, metallic compounds, cements, oxides, glasses, and polymers. Feedstock materials can be sprayed as powders, wires, or rods. The bond between the substrate and the coating may be mechanical, chemical, or metallurgical or a combination of these. The properties of the applied coating are dependent on the feedstock material, the thermal spray process and application parameters, and post treatment of the applied coating.

Nickel Chromium Boron Silica- Ball

Boiler tube Coating

HVOF Coating

High-Velocity Oxygen Fuel (HVOF) coating is a thermal spray coating process used to improve or restore a component’s surface properties or dimensions, thus extending equipment life by significantly increasing erosion and wear resistance, and corrosion protection. Coating thickness is usually in the range 0.1-2 mm. Characteristic features of HVOF sprayed coatings include their low level of porosity […]

Vessel Linings

Vessel Lining Coating Service is rapidly emerging as a corrosion-resistant lining material to suit specific working conditions with reference to temperature, the concentration of the product handled and the type of material, etc. Various grades of resins like isophthalic, bisphenol, vinyl ester & epoxy, etc are available. The advantage of F.R.P. is that this along […]