MIG Welding:

Gas metal arc welding (GMAW), sometimes referred to by its sub types metal inert gas (MIG) welding or metal active gas (MAG)welding, is a welding process in which an electric arc forms between a consumable wire electrode and the workpiece metal, which heats the workpiece metal, causing them to melt, and join. Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from contaminants in the air. The process can be semi-automatic or automatic. A constant voltage, direct current power source is most commonly used with GMAW, but constant current systems, as well as alternating current, can be used. There are four primary methods of metal transfer in GMAW, called globular, short circuiting, spray, and pulsed-spray, each of which has distinct properties and corresponding advantages and limitations.

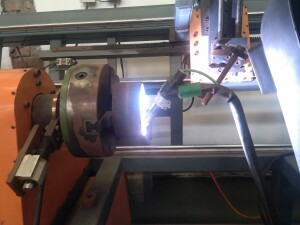

Cladding on Valve by automated MIG

MIG welding on Heat Exchanger Flange

TIG Welding:

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area is protected from atmospheric contamination by aninert shielding gas (argon or helium), and a filler metal is normally used, though some welds, known as autogenous welds, do not require it. A constant-current welding power supply produces energy which is conducted across the arc through a column of highly ionized gas and metal vapors known as a plasma.

TIG cladding in ID on Sleeve

TIG Welding on Screw Flight