Keepsake | Services

Our services include Thermal Spray Coatings, Welding/Cladding, Manufacturing & Automation

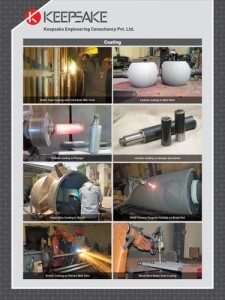

Thermal Spray Coatings:

1) Ceramic Coating,

2) Carbide Coatings / Tungsten Carbide Coatings / Chrome Carbide Coatings(Cermet)

3) Co base alloys(Stellate) Coatings

4) Ni base alloys Coatings

5) Hastalloy Coatings

6) PEEK Coatings

For Various Applications like Boiler Tubes, Vessels, Rolls, Screws, Shafts, Spindle Shaft, Drawing Pulleys, Capstans, Thermo wells, Decanters, Drive Rings, Plungers, Sleeves, Seals, Crank Shafts, etc.

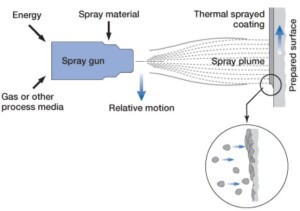

(Thermal spraying is a group of processes wherein a feedstock material is heated and propelled as individual particles or droplets onto a surface. The thermal spray gun generates the necessary heat by using combustible gases or an electric arc. As the materials are heated, they are changed to a plastic or molten state and are confined)

Welding/Cladding Technologies:

1) TIG

2) MIG

3) Plasma Transferred Arc(PTA)

4) Arc

Welding/Claddings:

1)Inconel

2) Stellite-1,Stellite-6,Stellite-12

3) Montel

4) Ni- base carbide

5) Ni/WC base carbide

6) Co- base carbide

7) Duplex

8) Fe - base carbide

9) Tungsten carbide

Various Application Like, Valves parts, Separator Can tube, Blades, Shafts, Pipe (ID & OD), Elbows, Screw, Dies, Sleeves, Plates, Heavy Rolls, etc.

Our services include Thermal Spray Coatings, Welding/Cladding, Manufacturing & Automation

Thermal Spray Coatings:

1) Ceramic Coating,

2) Carbide Coatings / Tungsten Carbide Coatings / Chrome Carbide Coatings(Cermet)

3) Co base alloys(Stellate) Coatings

4) Ni base alloys Coatings

5) Hastalloy Coatings

6) PEEK Coatings

For Various Applications like Boiler Tubes, Vessels, Rolls, Screws, Shafts, Spindle Shaft, Drawing Pulleys, Capstans, Thermo wells, Decanters, Drive Rings, Plungers, Sleeves, Seals, Crank Shafts, etc.

(Thermal spraying is a group of processes wherein a feedstock material is heated and propelled as individual particles or droplets onto a surface. The thermal spray gun generates the necessary heat by using combustible gases or an electric arc. As the materials are heated, they are changed to a plastic or molten state and are confined)

Welding/Cladding Technologies:

1) TIG

2) MIG

3) Plasma Transferred Arc(PTA)

4) Arc

Welding/Claddings:

1)Inconel

2) Stellite-1,Stellite-6,Stellite-12

3) Montel

4) Ni- base carbide

5) Ni/WC base carbide

6) Co- base carbide

7) Duplex

8) Fe - base carbide

9) Tungsten carbide

Various Application Like, Valves parts, Separator Can tube, Blades, Shafts, Pipe (ID & OD), Elbows, Screw, Dies, Sleeves, Plates, Heavy Rolls, etc.

Thermal Spray Coating

Welding Technologies

There are various types of Welding Technologies that we provide like: TIG Cladding & Welding Services Auto TIG/ Auto MIG/PTA welding can be used with SPM fixture which has provision to rotate the job, move the torch in X axis & Y axis. PTA torch has AVC to maintain constant arc length. The Welding & […]

Manipulators

Semi Auto Welder 1 Axis turn table designed specially for increased production rate and better job manipulation dynamics. Adjustable tail stock mechanism for accommodation of multiple job variants. Interchangeable option between tail stock and roller support. Multiple support functionality for longer and heavier jobs. Semi auto welder is cost effective and economical setup for entry […]

Thermal Spray Coatings

Thermal spraying is a group of processes wherein a feedstock material is heated and propelled as individual particles or droplets onto a surface. The thermal spray gun generates the necessary heat by using combustible gases or an electric arc. As the materials are heated, they are changed to a plastic or molten state and are confined […]

Manufacturing Components

Manufacturing Case 1 Equipment: Pump Name of the Part: Sleeves and Plungers Present Problem: A major expense associated with pump operation is replacement of sleeves/plungers. Wear on these components necessitates: Frequent packing adjustment to compensate for dimensional changes caused by wear. Packing material failure due to sleeve surface […]